What happens when a new business class seat undergoes a crash test?

Links on Head for Points may support the site by paying a commission. See here for all partner links.

Last week I went to Norfolk to watch a crash test of a new business class seat. Fortunately, I wasn’t in it during the test!

“What I’d like people to understand is how much work goes into an aircraft seat – any seat, not just business class. It’s not easy.”

That’s what Dave Yates-John tells me in the observation room of the UK’s largest Dynamic Test Facility in Norfolk.

I’ve driven up to see one of the development tests that new startup seat-maker Unum is undertaking for its flagship Unum One business class seat, which is due to be installed on a yet-unnamed customer’s Boeing 737s by late next year.

Unum is the UK’s latest startup seat-maker

Unum was founded in 2020 by industry veteran Chris Brady. It’s a small world: back in the nineties, Chris met Katie, our commercial director, at Virgin Atlantic, where they both worked. Virgin Atlantic is where Chris developed the ‘J2000’ angle-flat seat for Upper Class, the predecessor to the current old-but-still-flying coffin seat from 2003.

That seat:

“got launched about a year late, and unfortunately for Virgin Atlantic, it launched about three months after the BA (the arch-enemy) launched the Yin Yang seat” and the world’s first lie-flat business class seat.”

Then, as now, development and launch of new business class seats were often behind schedule.

“We hated the seat manufacturers because they were inflexible and late and they were interested in equipment (for airplanes) and not furniture (for people). I’ve subsequently made a career out trying to change it.”

After leaving Virgin Atlantic, Chris founded an innovative startup called FlightStore trying to bring online personal shopping to seat-back screens in 2000 “which was, in hindsight, about 10 years too early”.

Then, in the early noughties, he joined with “a couple of lads who used to work at Reynard Aviation” – the company that produced the J2000 seat for Virgin – and they founded Acro, a very successful economy class seat manufacturer.

Chris ended up running Acro before it was sold into Chinese ownership for “tons of money” in 2017. After working for the new owners for 15 months Chris left in January 2019 and his non-compete expired in October 2019. “We started talking about Unum in the Autumn of 2019 and founded it in Spring 2020, March.”

Spring 2020 was a terrible time to be working in the travel business but the timing could not have been better for Unum. With a development time of three to four years, designing and engineering a business class seat takes time and Unum is now in the home straight, just as airlines clamour to refurbish aircraft and install new business class cabins.

Meanwhile, manufacturers – and especially the dominant players such as Collins and Safran – cannot keep up with the demand as supply chains struggle to ramp up again.

Introducing Unum One

Unum One is the company’s flagship, reverse herringbone business class seat designed for single aisle aircraft.

“Back at Acro we sought and fought to make seats as slim as possible. That doesn’t mean they’re uncomfortable. Think of some of the classic 1950s chairs from Charles and Ray Eames, for example. They’re made out of plywood, but they’re still comfortable. They’ve got the right shaping to distribute pressure. Conversely, there are plenty of upholstered seats, notably, every single train seat that I’ve been in, that are really uncomfortable because the ergonomics don’t work.”

Core to the Unum One is a new, proprietary “scimitar” reclining mechanism that simplifies the seat but also makes it lighter. Whilst most business class seats weigh over 100kg each when fully dressed – Chris claims BA’s new Club Suite seat is 110kg – Unum’s comes in at 84kg.

Crucially, Unum isn’t trying to reinvent the wheel here:

“We weren’t trying to design a new category of seat here….whilst you can point at more than half a dozen things about our seat that sets it apart from its competitors, it’s very recognisably an outward facing herringbone seat, which is roughly half of all business class seats installed today.

Herringbone seats are good because they’re efficient, meaning you get lots of people in per square foot, but they’re bad because they have tapered and pointy footwells, and they’re bad because the footwell is not tall enough, because your footwell is the side console of the passenger in front. And if that side console is high, it’s unergonomic for me in front of you.”

The scimitar mechanism is crucial to solving these problems, and whilst I’m not allowed to show you any photos I can vouch for its simplicity. Chances are you’ve never, as a passenger, seen the underside of a business class seat but they are stuffed with complex mechanisms and actuators to ensure you can recline.

In contrast, the mechanics of Unum One is based on a simple – and in hindsight, obvious – idea. It is impressive.

But designing a business class seat is only half the battle. The real challenge is making it a reality in the highly regulated aviation industry.

“It has to be light enough, commercially viable and most importantly, comfortable for the passenger. Trying to get everything to align is incredibly difficult and a lot of people fail to do it well,” Dave tells me.

Test and test again

Chris explains:

“The basic certification of an airplane is predicated around a 90-second evacuation and suppressing fire for those 90 seconds. That’s something that Boeing and Airbus have to demonstrate with real, live testing, with naive users, that they can get everybody off in 90 seconds. Which is a bit of a feat on a fully loaded A350 or A380, frankly.

That’s a challenge for seat-makers, as it limits the materials they can use inside the cabin as they need to “suppress an aggressive kerosene-fuelled fire for two minutes without creating too much heat, any toxins or too much smoke to kill people before they get out the doors.”

Aircraft seats – all seats, not just business class – also need to withstand the impact a crash such as an emergency landing on land or water. This is called Dynamic Testing and is the reason why I’m in Norfolk.

Dynamic tests simulate the aircraft crashing in a survivable incident to test the structural performance of the seat and are broken down into a number of discrete tests. One involves subjecting the seat to a 16G deceleration from a crash landing where the airframe buckles and twists: the test is artificially twisted to simulate this, known in the jargon as ‘Pitch & Roll’. “You’ve got to make an aircraft seat that is floppy enough to absorb the shock. If it’s too stiff it can come off the tracks.”

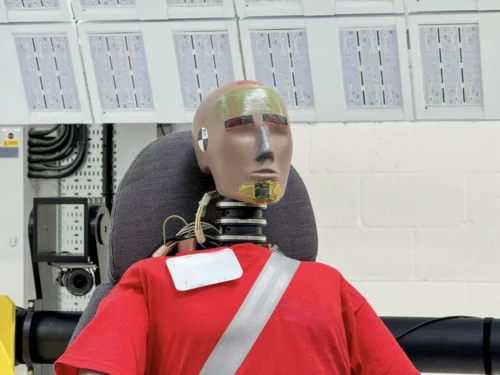

The test I have driven up to see is a so-called occupant injury test, and measures all forms of occupant injury. This is the one that involves a dummy rigged up to a computer to measure the forces across the entire body, from head and neck all the way down to knees and feet.

Dave, who is leading the development testing campaign, tells me that “this one is about the occupant and what injuries are sustained during a 16G impact.” The goal is to make sure the passenger is conscious and able to evacuate the aircraft, so no broken limbs .…

Unum has been performing these tests here at the facility “about once a month over the past two years”. There are 4 or 5 crash sleds in the UK (as the test facilities are called) which are used by automotive and aircraft designers to qualify their products. The one I visited today is the largest commercially available facility of its kind in the UK.

The 30m-long track is “the most technologically advanced available” and allows Dave and his team to automate a significant amount of the work. For example, the facility will automatically measure temperature and humidity and adjust its parameters to ensure the desired outcome – in this case a 16G impulse – is delivered.

The 16G force is delivered through a gigantic air ram. Think of it as a super-sized air rifle, but instead of shooting a projectile it launches a sledge with a seat down a 30m track.

The violence of the pulse is something to behold. If you were in the seat for the test , you’d weigh something like 1.3 tonnes (about the weight of a Mini) at the peak.

The whole thing is over in less than 200 milliseconds. In fact, it’s so fast that you’d literally miss it in the blink of an eye. Dave, who has led the development testing of the Unum One, tells me “there is a technique where you’ve got to just keep your eyes focused on something. You get about five or 10 seconds warning and you just don’t blink.”

This is in contrast to the hours spent setting up the test rig, with Dave and his team spending all morning setting up the seat and the dummy before the 3pm test fire.

Whilst the dummy is connected to a computer via an umbilical cord of cables and sensors that can measure the forces experienced with millimetre and millisecond precision, dyed Vaseline is also smeared on areas expected to impact the seat in front, including the head. This allows the team to see any areas of impact.

The whole thing is also filmed in super slow-motion at 1000 frames per second from every possible angle, allowing the team to review exactly what happened during the test.

Incredibly, and despite the high-density layout of a reverse herringbone configuration where the seat shell in front is relatively close to you, the dummy avoids a head collision entirely and passes with flying colours.

“It was a miss which is great, but what the regulations say in those circumstances are that you have to do a follow up test, because the dummy is a 50th percentile male, something like five foot eight.

So then you have to move the seat three inches closer to simulate a 95th percentile male, someone like me, six foot two, and then measure it. Testing is always a nervy experience and with the seats so much closer, the dummy is obviously going to clout it properly, pretty hard. And it did, but the magic number was 786, well below the regulatory threshold of 1000, so we’re home and dry as far as occupant injury is concerned.”

With the major manufacturers struggling to supply airlines as fast as they’d like – Lufthansa has started flying planes with a big gap where its new Allegris First Class cabin should be, because it is so delayed – Unum has an opportunity to pick off some of the smaller, more boutique airlines who don’t need hundreds of aircraft worth of seats:

“Smaller carriers are underserved; they don’t get the service they need from the big seat manufacturers, because there’s not enough capacity in the industry.”

One customer is already on board and will fit the Unum One seat aboard their Boeing 737 fleet. Although the exact identity of this customer remains secret, there are unlikely to be many airlines flying lie-flat business class seats on this aircraft type, although flyDubai and Singapore Airlines are amongst them. But whoever it is can rest assured that the seat has undergone rigorous safety testing

For now, however, Unum continues its rigorous safety testing with the aim of having the seat certified by spring next year. We’ll keep following their progress.

Rhys

Rhys

Comments (65)